The Sizing Systems

The sizes are found on the front of the packaging (circled in red )

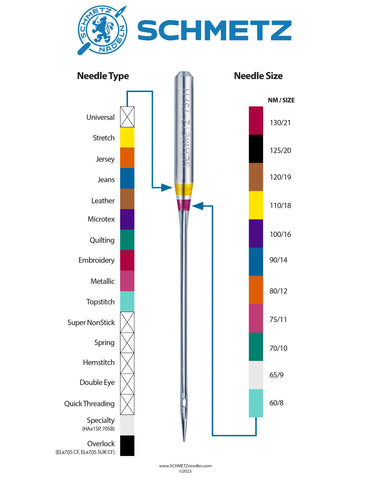

That first number is the Number Metric (shown as NM). This system was set up in the 1940's to standardize needle sizes.

It is simply the diameter of the needle shaft in millimeters multiplied by 100 to get rid of the pesky decimal places. That means that our standard "80" needle is really .80mm in diameter. (You're glad you asked, right?)

The larger the needle size, the stronger and thicker the shaft.

So where does the '12' of the 80/12 name come from?

It is nothing more than the merging of two measuring systems. The '12' comes from the corresponding Singer or US needle system. The '80', as we've learned, is the diameter of the shaft in millimeters multiplied by 100.

Here are some more specific examples:

- 60/8 – used for very fine fabric like lingerie, silk and fine lace.

- 70/10 – Net, Chiffon Lingerie, silk and cotton

- 75/11 – Voile, Chiffon, Organza, Denim, Satin, Sweater, Silk, Dress Shirt, Lycra, Spandex etc.

- 80/12 – Tricot, Silks, Canvas

- 90/14 – Syn Velvets, Poplin, Linen, Light Wool, Jersey, Muslin etc.

- 100/16 – Cord, Denim, Heavy Suiting, Corduroy etc.

- 110/18 – Heavy Denim, Leather, Upholstery Fabric, Faux Fur etc.

- 120/20 – Super heavy fabrics: Cord, Denim, Heavy Suiting

What to consider when choosing a sewing machine needle

- Thickness – Different needle sizes vary by thickness. Thicker needles sew through thicker, heavier fabrics while thinner needles are, of course, suited for fine fabrics like your silk and chiffon.

- Purpose – Also, different needle types have different shaped tips to best penetrate different types of fabric. For instance, leather-specialized needles are sharper than most other types.

- Thread – when using a fine, delicate thread, using a smaller needle size is recommended.

Sewing machine needles consist of several parts:

- The Shank (the flat and rounded part): This is the part you use to mount the needle on to the machine. It is the flat and round part you see on the needle.

- The Shaft: This is the length that spans from the end of the shank to the tip of the needle. It includes the Groove, the eye and the tip of the needle.

- The Groove: This is the rest of the needle that spans from the shaft down to the pointy tip, including the eye and the tip.

- The Eye: This is the part where the sewing thread passes through. The eye must work with the thread. For example, a topstitch needle has a bigger eye to accommodate a thicker thread.

-

The Point: Depending on the needle’s use, the point can be sharp or rounded. Standard needles are sharp while ballpoint needles have a rounded point like a ball.

The Colors of The Needles

Some needles are color coded. Manufacturers typically use colors to indicate the type of needle. However, when you are buying machine needles, don’t trust the color alone. Always make sure that you are picking the needle you want by looking at the text on the package.

This is because different manufacturers do not use color codes consistently. But if you stick to one brand, you should find similar needle types packaged with the same color on the package.

How Long Do Sewing Needles Last?

Needles are not made to last that long. It is common practice to replace sewing machine needles after about 6 – 8 hours of usage. This might seem like a short lifespan but since needles are cheap and easy to replace, why not do it frequently. It is the cheapest way to maintain your sewing machine.

What if you use the wrong sized needle? What Happens Then?

Different things can happen depending on the wrong needle size that you use. Here are some of the things you can expect:

- When the needle is too thin – When you use a needle that is too thin, it means that you have chosen a lower number than recommended for your fabric. The needle will snap easily. It might also bend a little, which is much worse. For example, if you use a fine needle on denim, it will surely bend, snap or skip stitches.

You might also get a bird nesting on the back of your fabric, which often happens when you make an ugly knot.

- When the needle is too thick – This means that you have chosen too high a number. When the needle is too thick, you’ll end up with wrinkles on the fabric. The needle will also leave holes in the fabric, or cause drags and snags on the fabric. This won’t look good at all, even though the needle will not be broken or damaged.